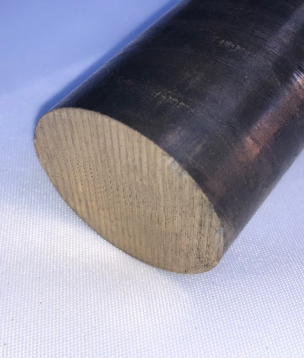

Description

| Weight | 0.52 lbs / in |

|---|

General Properties and Applications

Aluminum bronze is a type of bronze in which aluminum is the main alloying metal added to copper, in contrast to standard bronze (copper and tin) or brass (copper and zinc). A variety of aluminum bronzes of differing compositions have found industrial use, with most ranging from 5% to 11% aluminum by weight, the remaining mass being copper; other alloying agents such as iron, nickel, manganese, and silicon are also sometimes added to aluminum bronzes.

Aluminum bronzes are most commonly used in applications where their resistance to corrosion makes them preferable to other engineering materials. These applications include plain bearings and landing gear components on aircraft, guitar strings, valve components, engine components (especially for seagoing ships), underwater fastenings in naval architecture, and ship propellers.

Aluminum bronzes are in the highest demand from the following industries and areas:

- General sea water-related service

- Oil and petrochemical industries (i.e. tools for use in non-sparking environments)

- Specialised anti-corrosive applications

- Certain structural retrofit building applications

Aluminum bronze can be welded using the MIG welding technique with an aluminum bronze core and pure argon gas.

Reviews

There are no reviews yet.