So much of our world now includes plastics in almost all parts of everyday life in many positive ways. For instance, something as simple as an electric kettle often has several plastic parts. Acetal plastic is one of these plastics that has been widely adopted—for many good reasons. We detail what those are in addition to other important applications of acetal plastic below.

What Is Acetal Plastic?

Like nylon, HDPE, and UHMW plastic, acetal plastic is a thermoplastic. Thermoplastics are simply a kind of plastic that turns into a liquid at its melting point. However, they also have the ability to be heated, melted, cooled, and heated again without significant degradation.

This makes them more utilitarian like metals that can also be easily reused (i.e. steel and aluminum). It also makes it easy to recycle acetal plastic, making it a more environmentally-friendly material when re-used.

Celcon, Duracon, Kepital-POM, Tecaform, Tepcon, Hostaform, and Ultraform are the main brands to choose from when it comes to buying acetal plastic. Bear in mind the plastic is usually sold in granulated form. However, Millennium Alloys offers ready-made sizes and shapes of acetal plastic to be used right away for any project.

The 2 Types of Acetal Plastic

Unlike other plastics, acetal comes in 2 main forms:

- Acetal homopolymer

- Acetal copolymer

Each has its own benefits and drawbacks making them helpful for some tasks over others.

What Is Acetal Homopolymer?

Acetal Homopolymer is made up of repeating monomer units with a similar molecular structure exhibited by each unit.

Some of the notable benefits include high room temperature strength and tensile strength. It’s also more rigid than acetal copolymer. Some additional properties include:

- Slightly higher operation temperature

- Slightly more hardness

What Is Acetal Copolymer?

Acetal copolymer differs from acetal homopolymer in that instead of repeating monomer units, it’s instead made out of different types of monomer units, which combine to form a common polymer structure.

This makeup gives it the advantageous properties, compared to homopolymers, of better and both more dimensional stability and resistance to abrasion. It’s also less porous when extruded.

The Benefits of Acetal Plastic

Compared to other kinds of plastics, acetal plastic stands out for its superior corrosion resistance as its most noteworthy advantage. Acetal homopolymers can resist corrosion or degradation in freshwater, saltwater, solvents, oils, reagents, and alkalis.

Acetal’s other properties also contribute to its usefulness though. The plastic possesses high tensile strength, excellent dimensional stability, and low friction and thermal expansion. It’s also highly abrasion-resistant making it very durable and has low water absorption properties making it perfect for use on both land and in the water.

Another element that contributes to its strength as a material is its superior creep resistance. Creep resistance refers to the tendency for a material to stay bent if left under stress for too long. Since acetal plastic’s is so high, it better returns to its original shape when the stress it’s under is lifted.

Because of the many aforementioned benefits, acetal plastic is highly versatile and can be found in a huge variety of applications.

Applications of Acetal Plastic

You probably won’t go a day without using something in your daily routine that has acetal plastic in it. It’s easily one of the most popular types of plastic that’s used worldwide.

Consumer Applications of Acetal Plastic

Due to the prevalence of acetal plastic, you may even be using something right now that includes it. In electronics, it’s used for insulating components, connectors, and parts of various consumer electronic devices.

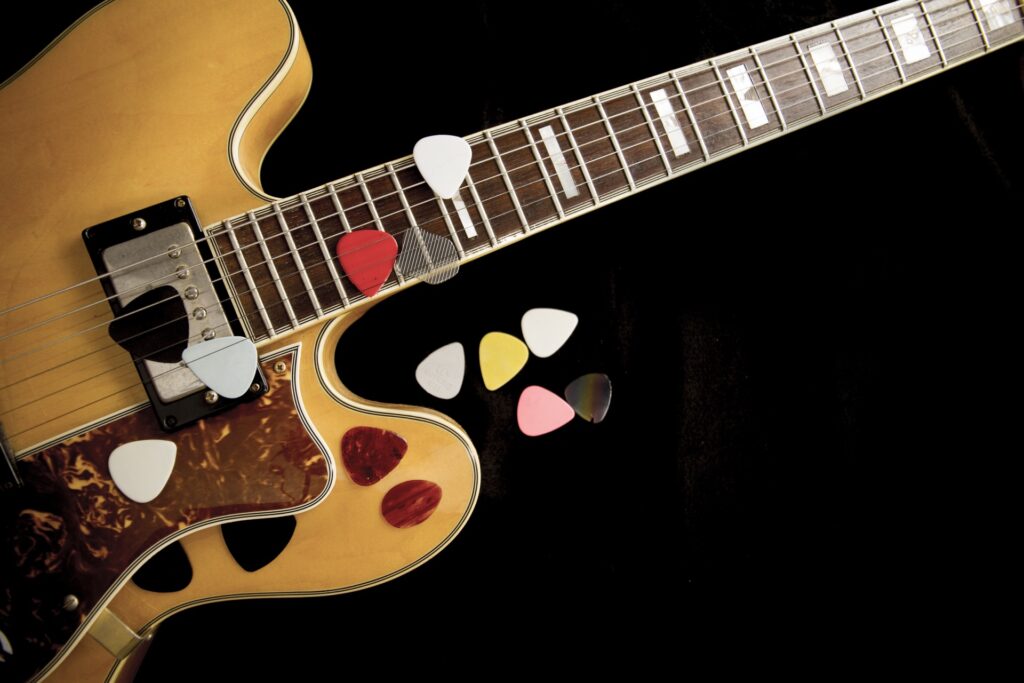

You’ll also find the plastic in coffee brewers and knife handles. In the music industry, acetal plastic is used in guitar picks, bagpipes, instrument mouthpieces, flutes, and drumstick tips.

Acetal Plastic Applications in Manufacturing and Construction

Naturally, with acetal plastic’s high durability due to its abrasion and corrosion resistance, it can be found in a wide variety of construction applications. Some of the most notable ones include structural glass, conveyors, gears, pulleys, rollers, bearings, bushing, cams, valves, seals, gear wheels, fasteners, and lock systems.

In the automotive world, you can find acetal plastic in many parts including vehicle fuel sender units, power windows, door locks, turn signals, and vehicle tanks (just to name a few).

Overall, acetal plastic is immensely versatile and a key material in many objects and tools we use daily.