Although it’s easy to mistake for a natural fibre, Nylon is actually a type of thermoplastic used in a wide variety of industries. Due to its relatively lightweight nature, but high strength, some of the most common uses of nylon are ropes and threads as it’s immensely flexible and can maintain its structure in a multitude of conditions.

Below we detail further what the material is, how it’s made, and why it continues to be so widely adopted as a go-to material for numerous applications.

What Is Nylon?

As mentioned previously, nylon is a thermoplastic which refers to how the plastic responds to heat. In the case of nylon, it turns into a liquid at very high heat—220℃ specifically.

Thermoplastics like nylon are some of the most long-lasting kinds of plastic because even when they are heated to their melting point, cooled, and reheated again they still retain much of their durability. Since they don’t burn when they reach their melting point, they can also be reformed into new shapes by being injected into new moulds.

Why Nylon Is So Useful: It Has Many Beneficial Properties

Aside from its high durability, nylon has many other properties that make it so widely used.

Like other kinds of plastics, nylon has a low coefficient of friction. While it doesn’t possess the lowest friction coefficient compared to other plastics, it’s still excellent for applications that involve a component seeing a lot of wear.

As alluded to previously, nylon is also very strong, but it’s also elastic, making it perfect for many clothing items. Plus, it’s easy to wash, dries quickly, and retains its shape after going through the laundry. The material is also relatively resilient to heat, UV rays, and chemicals.

Common Uses of Nylon

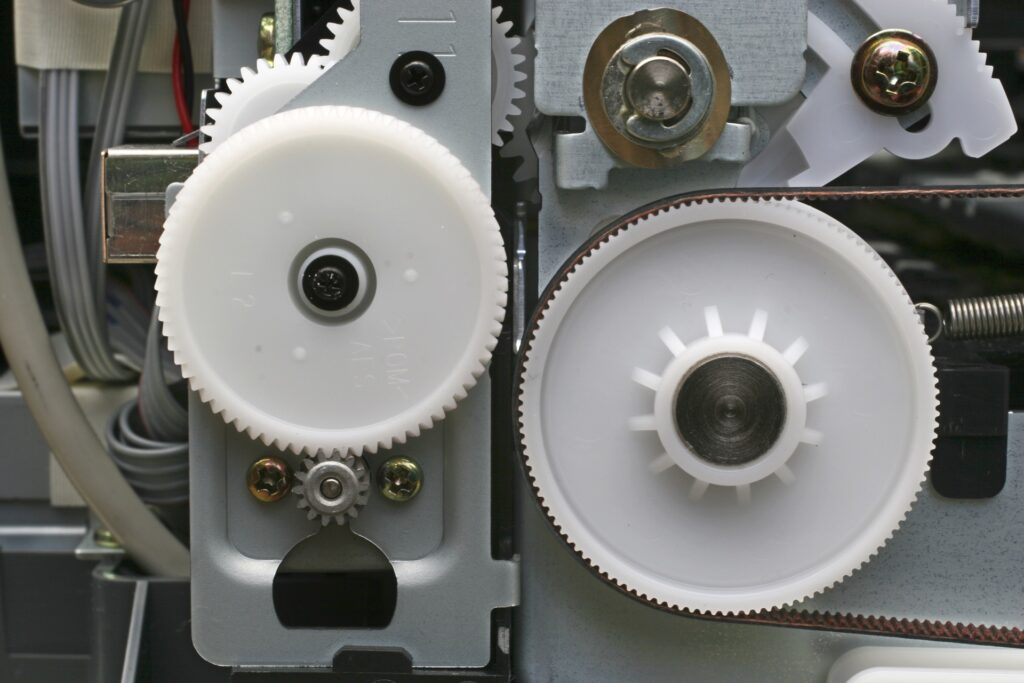

All of these properties make nylon a frequently-used material in a myriad of applications. For instance, it’s often used in gears, brushings, and plastic bearings due to its durable, and low-friction properties.

When the material was first invented, it was initially put into toothbrushes—an application that’s still one of its most common uses today. Shortly after though, nylon stockings took off in popularity—another application that’s also used in present day. Nylon is actually one of the most common materials in clothing, especially in athletic wear due to its quick-drying nature and elasticity.

The material’s resistance to both cold and heat in combination with its strength and lightweight nature make it a natural choice for using a rope. In fact, nylon ropes are some of the strongest and are frequently used in marine applications for towing and docking. In addition, it also offers greater resistance to shocks that would break ropes made of more natural fibres.

How Are Nylon Fibres Made?

Nylon fibres are made by pushing molten nylon through tiny holes in a spinneret which then harden when exposed to the air. After they have cooled down, these filaments are formed into bobbins and stretched out. Then, through a process called “drawing,” the filaments are unravelled and wound into a spool. Through this process, the molecules in the filament form parallel lines. This is one of the most important parts of production as this provides the nylon fibre with its elasticity and strength.

Clearly, nylon is a well-rounded material suited for a wide array of applications and uses. With its simple means of production and significant beneficial properties, nylon will no doubt continue to be a popular material for many years.