Aluminum is already one of the most versatile metals out there, but anodizing it offers even more applications. In fact, there are plenty of common uses of anodized aluminum you may not even realize involve aluminum being anodized.

Below, we’ll detail some of these applications, what the anodizing process actually does, and the benefits of the anodizing process as well.

What Is Anodized Aluminum?

Anodizing itself is an environmentally-safe electrochemical process that converts the aluminum metal surface into porous aluminum oxide, thus forming an end product whose finish is much more durable and weather-resistant than before. Naturally, this is desirable for many different applications, especially those outdoors or frequently exposed to harsher weather.

Anodized aluminum often has a more pleasing look to it that makes it a frequent pick for everything from artwork to commercial structures.

Aluminum also isn’t the only metal that can be anodized. Steel and titanium are other common metals that are anodized often as well.

Benefits of Anodized Aluminum

Aluminum Becomes Even More Corrosion Resistant

Aluminum is already highly corrosion-resistant on its own, but through anodizing, it can last without corroding for much longer. Aluminum (or anodized aluminum) won’t ever rust, but it can still corrode when exposed to moisture, air, salt or other corrosion-inhibiting compounds or elements.

However, anodizing the metal will delay this process from happening for significantly longer.

It Becomes Easier to Lubricate

Aluminum is too smooth to retain lubrication, but anodizing it changes that. Once anodized, the metal gets deeper pores that allow it to retain a lubricating oil or film.

Anodized Aluminum Can Be Easily Dyed

Standard aluminum can’t easily be coloured, or dyed, but that’s not the case with anodized aluminum. Through the process of anodizing, chemicals trigger the formation of a thicker oxide layer as well as a porous surface. It’s this porous surface that allows dyes and colours to stick to the aluminum.

Common Uses of Anodized Aluminum

Anodized aluminum is often found in 3 main industries:

- Construction and architecture

- Consumer goods

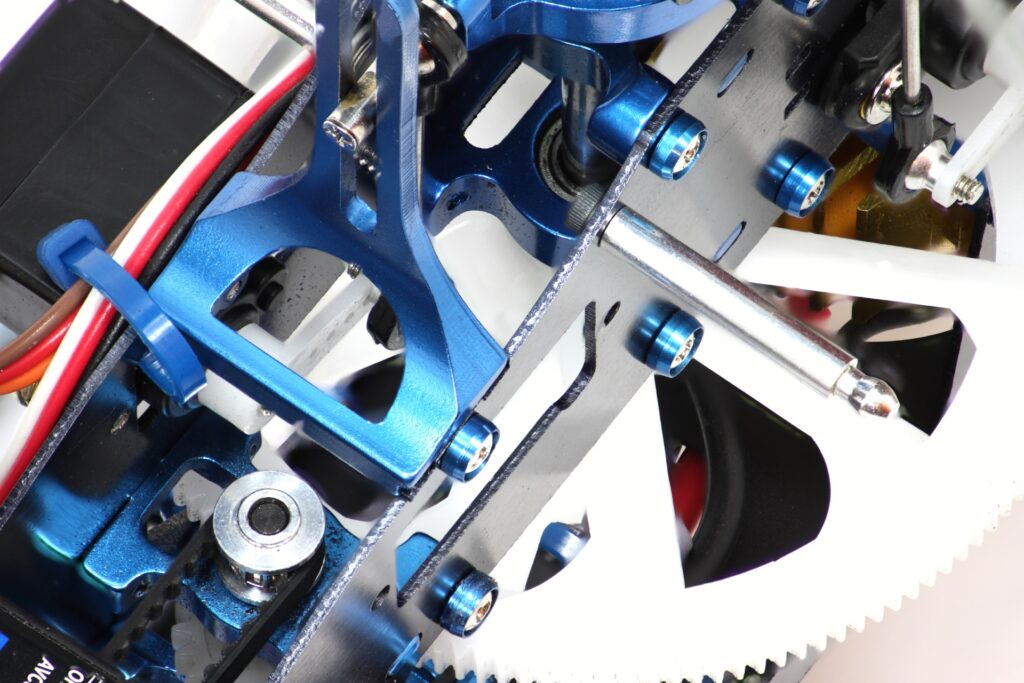

- Mechanical components

The construction and architecture industry uses anodized aluminum in many, many different ways. Some of the most common things are structural components, decorative artwork, and both commercial and residential building products.

Consumer goods also cover a wide range of applications. You can commonly find anodized aluminum in appliances, food preparation equipment, sporting goods, and jewelry.

Finally, mechanical components refer mainly to their use in vehicles like cars, boats, and other motor vehicles.

Notable Applications of Anodized Aluminum

Of course, although the applications we mentioned above are some of the most common uses, anodized aluminum isn’t just a kind of metal that’s excellent on earth, it’s also used in space.

The NASA international space station (ISS) actually uses anodized aluminum in its trusses. Because the anodized surface finish of the aluminum trusses better distributes heat, the surface of anodized aluminum doesn’t get as hot. This is especially helpful in space where there’s not an atmosphere of protection from the sun like we have on Earth.

Trusses are the only component in the space station that uses anodized aluminum either. Handrails on the outside of the station also used anodized aluminum. These handrails are both anchors and lifelines for every ISS astronaut and anodized aluminum with its durable nature is a perfect choice.

Clearly, anodized aluminum is one of the best choices of metal for a wide range of applications and uses and will continue to be for years to come.