Plastic is one of the most common materials in the world, to the point where it’s rare for most Canadians to go a day without using some object that has plastic in it. One of the most crucial plastics used for building a variety of components is polycarbonate plastic (PC plastic). There are actually many interesting facts about polycarbonate plastic as it’s highly versatile in its application.

Below, we detail some of the facts about the material you may not be aware of.

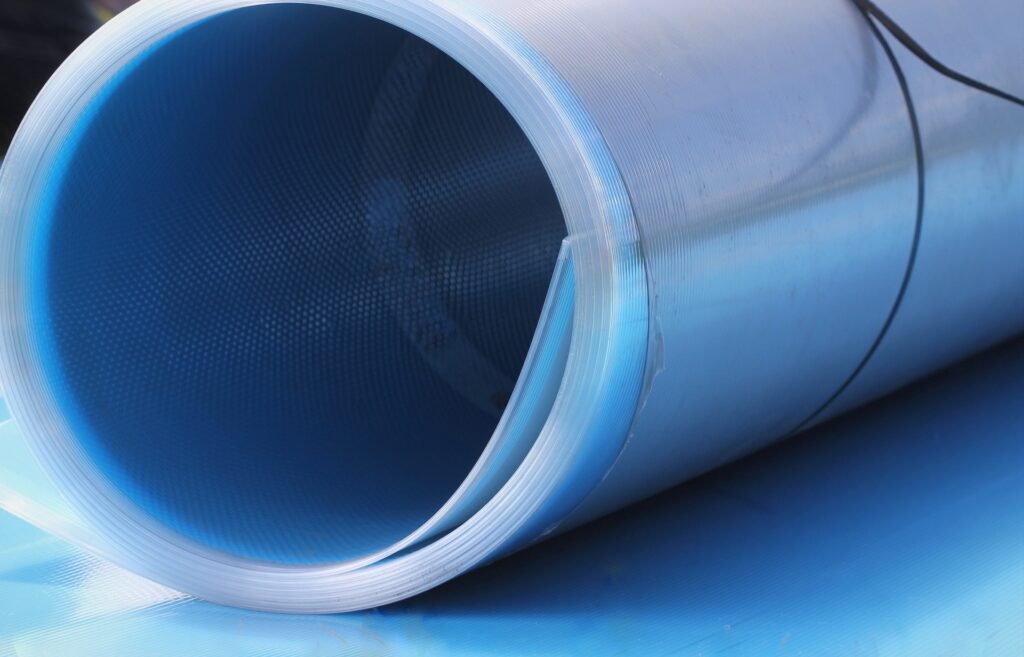

Polycarbonate Plastic Is Incredibly Tough and Durable

Almost unbreakable, PC plastic is very strong as a material. It can maintain its structure in temperatures up to 140°C and down to -20°C making it an ideal choice for locations where the weather fluctuates often. Because of this ability, it’s classified as a thermoplastic.

The material’s strength extends to its impact and fracture resistance which is a large reason why it’s so tough.

In addition to all of these amazing properties, PC plastic also has good chemical resistance. It’s able to shrug off diluted acids, aliphatic hydrocarbons, and alcohols. It also has a moderate level of chemical resistance to oils and greases as well.

Polycarbonate Plastic Can Be Better Than Glass

Clear PC plastic can actually transmit over 90% of the light that passes through it. This, combined with its lightweight construction, make it a frequent alternative pick when glass is too heavy for the application.

Because of both these properties, polycarbonate plastic is often used in eyewear – particularly in sunglasses – as the plastic can be made to block UV radiation.

Aside from sunglasses and other eyewear, tinted PC plastic is also used in other applications. One notable use is for applications when reducing glare is important. This is often as simple as covering lighted signs on the highway to ensure drivers aren’t blinded when light hits the sign in a certain way.

Polycarbonate Plastic Can Be Used in 3D and CNC Printing

While not all 3D printers can use PC plastic because the material is a thermoplastic it can be used in some of them. This is often done using the FDM process. The material is purchased in filament form and the 3D printer then heats and deposits the filament into your desired 3D shape.

PC plastic for 3D printing rarely comes in a variety of colours, however. Most frequently, it’s limited to a shade of white. PC/ABS blends are also available for 3D printing on an FDM machine.

Researchers Are Working on Developing a Reliable Form of Bio-Polycarbonate Plastic

Finally, one of the most promising developments in the plastic manufacturing world is relying less on synthetic materials to create PC plastic and instead incorporating more organic materials into the manufacturing process.

Several companies are working on this although many are approaching the problem from different angles. Two companies, Mitsubishi Chemical Corporation and Roquette, are focusing on creating PC plastic using plant bases. These have shown promising results in improving the transparency and optical homogeneity and providing enhanced chemical, UV, and scratch resistance.

SABIC, another company working on a more bio-form of polycarbonate plastic, is using feedstock to make the material more environmentally friendly. Finally, researchers at the Korea Research Institute of Chemical Technology (KRICT) have even made breakthroughs in making the material from glucose (i.e. sugar).

Overall, PC plastic has become a core building component of our modern world. Both its amazing properties and further research into making it an even better material mean it’s likely going to be around for many more years to come.