Aluminum bronze is a distinctive and versatile alloy that stands out in various industries. Its unique composition and properties make it a valuable material in applications ranging from industrial machinery to architectural design. If you’re curious about this alloy’s advantages, uses, and suitability for your project, this guide is tailored to provide clarity and insight.

What Is Aluminum Bronze?

Aluminum bronze is a specialized alloy primarily composed of copper and aluminum, with other elements such as iron, nickel, and manganese added to enhance its mechanical and chemical properties. This alloy is renowned for its excellent corrosion resistance, durability, and aesthetic appeal.

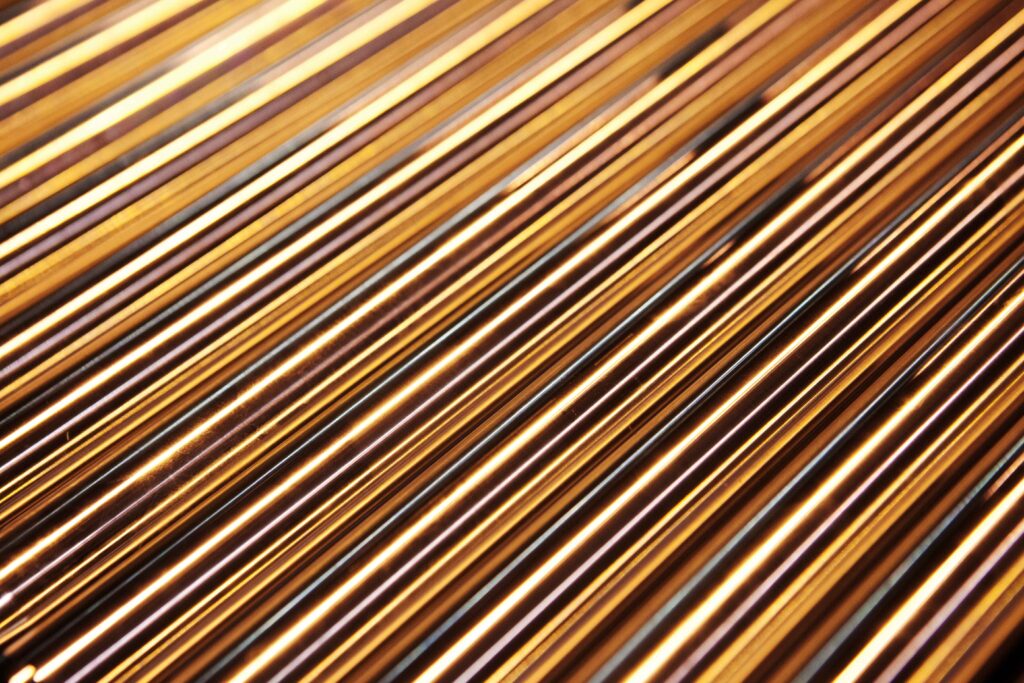

The percentage of aluminum typically ranges from 5% to 12%, giving the alloy its unique blend of strength and resilience. Its attractive golden hue further adds to its desirability in architectural and decorative applications.

Features of Aluminum Bronze:

- Corrosion Resistance: Excellent performance in marine and chemical environments.

- Durability: High strength-to-weight ratio and exceptional wear resistance.

- Aesthetic Versatility: Its golden sheen enhances its visual appeal.

Whether in the form of aluminum bronze flat bars, cast components, or machined parts, this alloy offers unmatched performance.

Benefits and Drawbacks of Aluminum Bronze

Like any material, aluminum bronze has strengths and limitations. Understanding these helps in making informed decisions for your specific project needs.

Advantages:

- Unmatched Corrosion Resistance: Ideal for marine applications, aluminum bronze is highly resistant to saltwater and harsh chemicals.

- High Tensile Strength: It outperforms many other alloys in terms of durability, reducing wear and tear in demanding applications.

- Low Maintenance Costs: Its longevity minimizes the need for frequent replacements or repairs.

- Versatility in Applications: Available in various forms, including bronze aluminum flat bars, sheets, and castings, aluminum bronze suits multiple industries.

Disadvantages:

- Cost

- Aluminum bronze alloy tends to be more expensive than traditional bronze or other metals.

- Complex Machinability: While its strength is a benefit, it may require specialized tools for shaping and machining.

Despite these challenges, the long-term benefits often outweigh the drawbacks, especially in high-stakes environments.

Is Aluminum Bronze Harder Than Bronze?

A common comparison involves the hardness of bronze aluminum versus traditional bronze. Due to its higher aluminum content, aluminum bronze is significantly harder, with superior wear resistance.

Where Hardness Matters:

- Marine Industry: Bearings and propellers.

- Industrial Applications: Components exposed to high stress and friction.

Its enhanced hardness and mechanical properties make it the preferred choice in heavy-duty settings.

Diverse Applications of Aluminum Bronze

The utility of aluminum bronze alloys spans a broad spectrum of industries, thanks to its durability and corrosion resistance.

- Marine Engineering

- Aluminum bronze flat bars and castings are essential in creating ship propellers, underwater fasteners, and valves that endure saltwater exposure.

- Aerospace Components: Used in aircraft landing gear and hydraulic systems, aluminum bronze provides strength without adding excessive weight.

- Industrial Machinery: Bearings, gears, and pump components made of aluminum bronze ensure longevity and reduced downtime.

- Architecture and Design: Beyond functionality, its golden hue makes it a favourite for decorative railings, door handles, and structural elements.

- Chemical Processing: Valves and fittings made from bronze aluminum resist chemical corrosion, making them ideal for handling acidic or alkaline substances.

- Oil and Gas Industry: This alloy is also used for components in harsh environments, such as pipelines, where both strength and corrosion resistance are critical.

How to Decide if Aluminum Bronze Is Right for Your Project

Choosing the right material for a project involves assessing specific requirements. Here’s how to determine if bronze aluminum aligns with your needs:

Ask These Questions:

Will the material be exposed to corrosive environments? For marine or chemical settings, aluminum bronze excels.

Do you need a durable, high-strength solution? This alloy is perfect for high-stress applications like industrial machinery.

Are aesthetics important? Its unique golden sheen adds a touch of elegance to architectural designs.

Does the budget align with long-term benefits? While pricier upfront, aluminum bronze’s durability and low maintenance can justify the investment.

Working with Millennium Specialty Alloys

To ensure you’re sourcing premium-quality materials, consider Millennium Specialty Alloys. We provide top-tier aluminum bronze alloys, from flat bars to custom components, tailored to your project’s specifications. Our commitment to quality makes them a trusted partner across industries.

Why Bronze Aluminum Stands Out

Aluminum bronze composition offers an exceptional blend of properties that few other alloys can match. Its combination of strength, corrosion resistance, and versatility ensures it remains a top choice for industries requiring reliable performance under challenging conditions.

Whether you’re working on a high-tech aerospace project, designing durable marine equipment, or creating visually stunning architectural elements, aluminum bronze is the material that can meet—and often exceed—expectations.