Nylon is one of the most versatile and widely used engineering plastics on the planet. From high-performance industrial applications to everyday essentials, nylon material has earned its reputation as a go-to thermoplastic thanks to its durability, elasticity, and cost-effectiveness. Whether you’re exploring nylon tube or nylon sheets, understanding how this material works and why it’s such a popular choice can help you select the best product for your needs. In this guide, we’ll walk through the most important facts about nylon material, including its properties, uses, manufacturing process, and how it stacks up against other industrial plastics.

What Is Nylon? Understanding This Versatile Thermoplastic

Originally developed in the 1930s, nylon was the first synthetic fibre to enter mass production. Today, it belongs to a family of thermoplastic polymers known for their ability to melt and re-solidify without degrading, making them ideal for reshaping and repurposing.

As a thermoplastic nylon, this material becomes soft and moldable at high temperatures specifically around its melting point of 220°C and solidifies upon cooling. This property is what allows nylon tube and nylon sheets to be custom-formed to exact specifications during production. Because of its unique combination of strength and flexibility, nylon material has become indispensable in applications ranging from mechanical parts to textiles, electrical insulators, and marine-grade components.

Key Nylon Properties: Strength, Flexibility & Resistance

What sets nylon material apart from other plastics is its extraordinary blend of mechanical and chemical properties:

1. High Strength & Durability

Nylon is a high strength plastic, capable of withstanding heavy loads and tension without tearing or deforming. That’s why nylon tube and nylon sheets are commonly used in construction, automotive, and machinery manufacturing.

2. Elasticity & Flexibility

Unlike more brittle plastics, nylon is an elastic plastic it stretches under stress and bounces back without permanent deformation. This makes nylon material ideal for moving components and dynamic assemblies.

3. Low Friction Surface

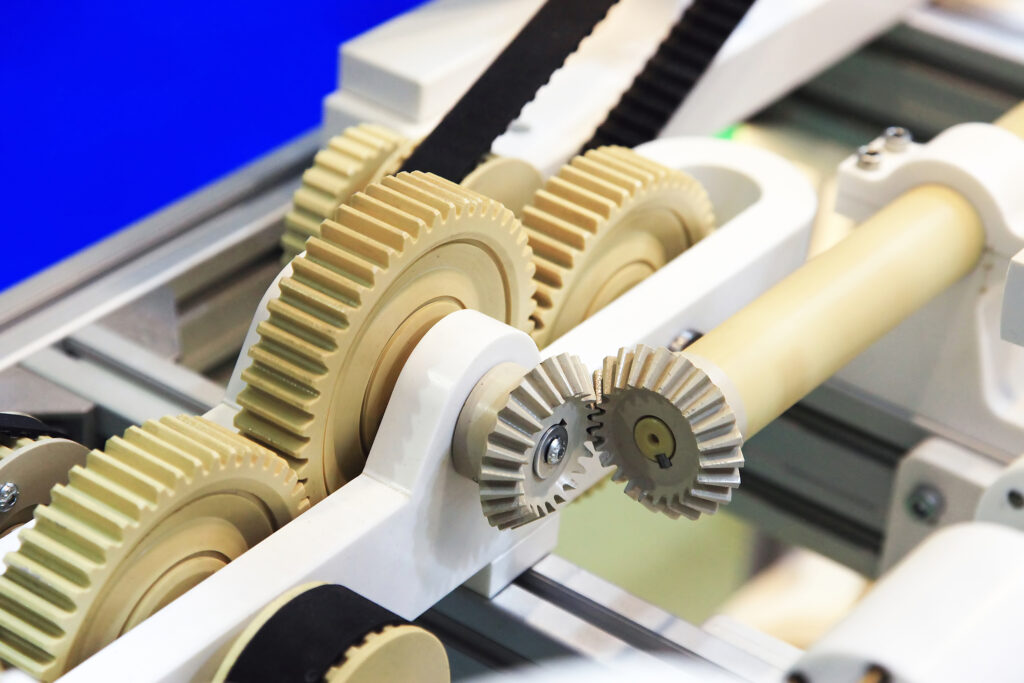

With a low coefficient of friction, nylon reduces wear and tear between moving parts. As a low friction plastic, it’s often found in gears, bearings, bushings, and slide pads where smooth operation is key.

4. Thermal & UV Resistance

Nylon stands up to extreme environments. As a heat resistant plastic, it tolerates high operating temperatures, and its UV resistant plastic nature helps it maintain structural integrity even under prolonged sun exposure.

5. Chemical Resistance

Many industrial settings require plastics that can handle exposure to oils, solvents, and cleaning agents. Nylon fits the bill as a chemical resistant plastic, making it perfect for tough, corrosive environments.

Nylon Tube & Sheets: Common Applications & Benefits

At Millennium Specialty Alloys, nylon tube and nylon sheets are among the most in-demand thermoplastics and with good reason. Their versatility, combined with an ideal balance of strength, weight, and machinability, makes them indispensable across a broad range of industries.

Nylon Tube Applications:

-

Hydraulic Systems

Nylon tube is often used to transport hydraulic fluids due to its chemical resistant plastic properties and high flexibility. It holds up under pressure, resists swelling, and doesn’t degrade easily which makes it ideal for complex routing where rubber or rigid piping would fail. -

Cable Protection

In both commercial and industrial settings, nylon tube acts as a tough barrier that prevents abrasion, moisture, and chemical damage to wiring systems. Its low friction plastic properties allow for easier wire pulls during installations. -

Machine Components

Used for rollers, bushings, and sleeves, nylon tube provides durable plastic performance in repetitive motion applications. It minimizes downtime by reducing wear and increasing part longevity.

Nylon Sheet Applications:

-

Wear Pads & Liners

Nylon sheets are commonly cut and shaped into wear strips or liners to prevent metal-on-metal contact. Their low friction surface makes them perfect for conveyor systems, hoppers, and chutes. -

Machined Parts

With its excellent machinability, nylon sheets can be precision-milled into everything from sprockets to spacers and gaskets. It’s a smart substitute for metal when weight and corrosion resistance are concerns. -

Structural Supports

Despite being lightweight, nylon material is a high strength plastic. Nylon sheets can be used as support plates, covers, and even temporary structural elements in environments that require chemical or moisture resistance.

Key Benefits of Nylon Tube & Nylon Sheets:

-

Customizable sizes and formats — available in various diameters, thicknesses, and lengths to suit your specs

-

Excellent machinability — can be drilled, milled, and turned without cracking or splintering

-

Cost-effective — ideal for both rapid prototyping and high-volume production

-

Indoor and outdoor durability — resistant to weather, UV rays, and temperature extremes

-

High strength-to-weight ratio — lightweight for easy handling without sacrificing structural integrity

-

Chemical & corrosion resistance — ideal for environments with oils, fuels, solvents, or cleaning agents

-

Smooth finish — creates less drag and wear in dynamic systems

Whether you’re engineering custom mechanical parts or building weatherproof components for outdoor environments, nylon tube and nylon sheets offer dependable performance across nearly every sector from manufacturing and construction to agriculture and marine operations. Their unique combination of properties makes them an exceptional choice when reliability, longevity, and adaptability matter most.

How Nylon Is Made: The Nylon Fibre Manufacturing Process

The nylon manufacturing process begins with the polymerization of monomers usually adipic acid and hexamethylene diamine to form nylon salt. This mixture is heated to form a molten polymer that can then be processed into different forms.

Nylon Fibre Production Steps:

-

Melting: The raw polymer is heated above the nylon melting point.

-

Extrusion: Molten nylon is pushed through spinnerets to form long strands.

-

Cooling: The extruded strands are exposed to air, allowing them to solidify.

-

Drawing: The fibres are stretched to align molecules, increasing nylon fibre strength and elasticity.

-

Finishing: The fibres are cut or spooled for textile or industrial use.

For solid shapes like nylon tube and nylon sheets, the process involves casting or extrusion into molds, followed by cooling and cutting. The ability to reshape and reuse thermoplastic nylon also makes it highly sustainable compared to thermosetting plastics.

Why Choose Nylon? Comparing It to Other Industrial Plastics

When it comes to choosing the right material for your project, nylon material stands out in a crowd of industrial plastics.

| Property | Nylon Material | PVC | Polyethylene |

|---|---|---|---|

| Strength | High | Moderate | Low |

| Flexibility | Excellent (Elastic) | Poor | Moderate |

| Heat Resistance | Up to 220°C | ~60–80°C | ~80–100°C |

| Friction Coefficient | Low | Moderate | Moderate |

| Chemical Resistance | High | Moderate | High |

| Machinability | Excellent | Moderate | Low |

Choosing nylon tube or nylon sheets over alternatives like PVC or polyethylene gives you a better balance of performance and longevity, especially in high-stress or high-temperature environments. At Millennium Specialty Alloys, we help you choose the best nylon material for your application, whether you’re looking to reduce friction, increase resilience, or simply need a thermoplastic that performs under pressure.

Conclusion: Nylon’s Value in Modern Manufacturing

From its remarkable elasticity to its chemical and heat resistance, nylon material remains a staple in both everyday and industrial-grade solutions. Its combination of lightweight strength and flexibility makes nylon tube and nylon sheets essential components in industries ranging from automotive and aerospace to construction and marine. Whether you’re building, repairing, or innovating, nylon material delivers the performance and adaptability your project needs.

Looking for Nylon Tube or Sheets?

Millennium Specialty Alloys supplies high-quality nylon material in various formats, including custom-cut nylon tube and nylon sheets tailored to your needs. Contact us to discuss your project, get expert guidance, and receive a quote for the right thermoplastic nylon solution today.