Demystifying Sheet Metal Welding and Fabrication

Welding and fabrication are crafts that have stood the test of time, evolving and adapting as technology advances. Today, we are going to delve into the vast and captivating world of sheet metal welding and fabrication, answering some of the most common questions posed by both seasoned professionals and enthusiastic beginners alike.

1. Stick Welding Sheet Metal

Stick welding, or Shielded Metal Arc Welding (SMAW), is not the most common method for welding sheet metal due to the high level of heat input. However, it’s not impossible. Patience, skill, and a low amperage rod can do the trick. The key is to maintain a short arc length, use a whip-and-pause technique, and avoid overheating the metal to prevent burn-through.

2. Welding Car Sheet Metal with Flux Core

Absolutely! Flux core welding is a practical choice for welding car sheet metal. The process involves using a wire with a flux material in the center, eliminating the need for a separate shielding gas. While it may not give the cleanest finish, it is efficient and highly suitable for outdoor applications due to its resistance to wind.

3. Fusing Sheet Metal with Heavy Hammer Blows

While it’s a romantic notion reminiscent of blacksmiths of yore, fusing or welding sheet metal using heavy hammer blows alone isn’t feasible. Welding requires intense heat to melt the metal, creating a molten pool that fuses the pieces together as it cools and solidifies.

4. MIG Welding Sheet Metal without Warping

Metal Inert Gas (MIG) welding is ideal for sheet metal. However, warping can be an issue due to heat. To prevent this, use a lower heat setting, maintain a proper travel speed to minimize heat input, and distribute heat evenly by using intermittent welding or a stitch welding technique.

5. Bending, Welding, and Cutting Aluminum Sheets

Working with aluminum requires a specific set of tools and techniques. To bend aluminum sheets, a brake press is often used. Welding can be achieved with either MIG or TIG welding, both requiring a clean surface and proper shielding gas, typically argon. Cutting aluminum can be done using a variety of tools such as a band saw, jig saw, or plasma cutter depending on the thickness.

6. Understanding Metal Welding and Fabrication

Metal welding is the process of joining two or more pieces of metal by applying heat, while fabrication is the process of cutting, bending, and assembling metal structures from various metal pieces and parts.

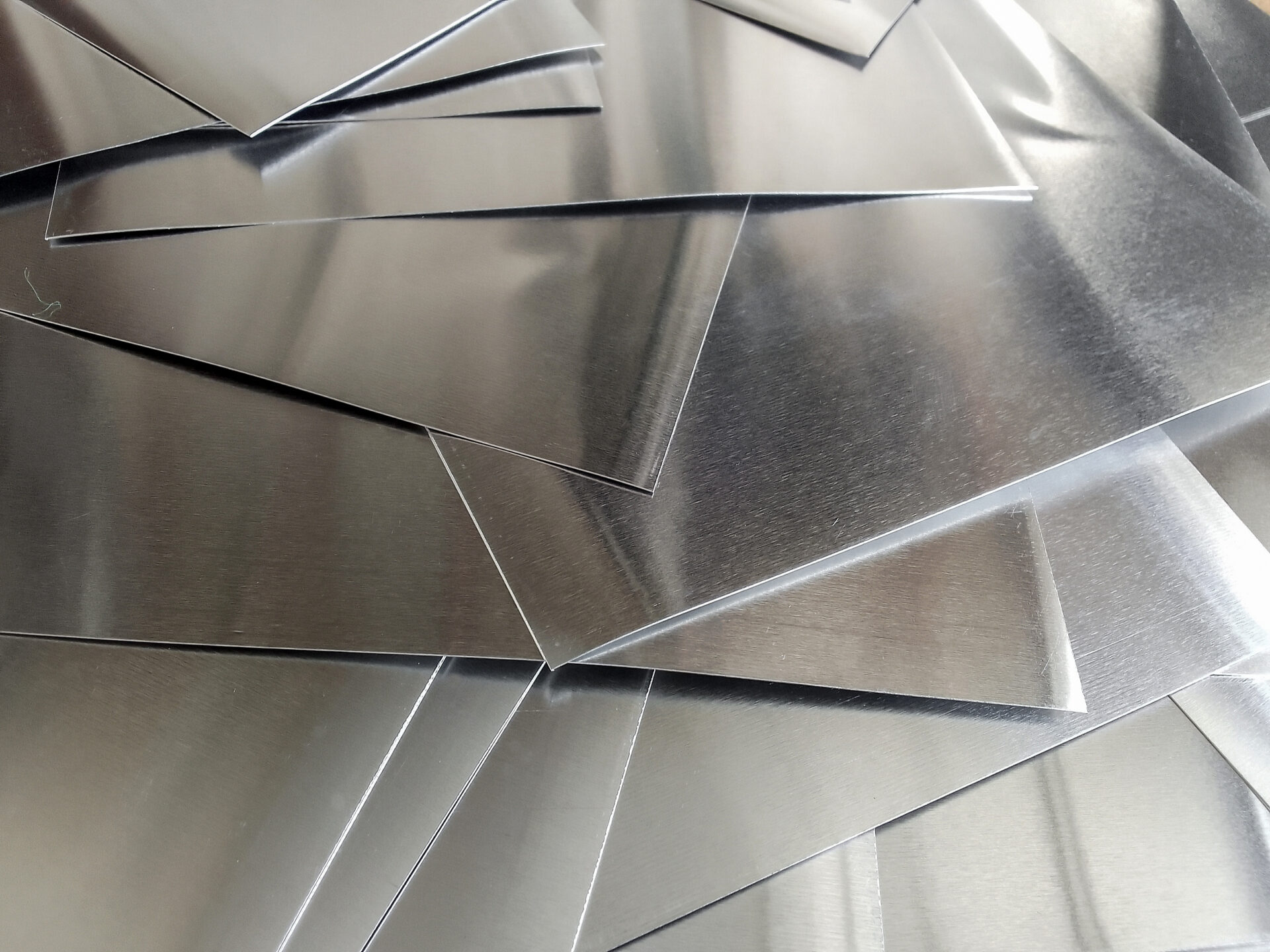

7. Types of Sheet Metal Fabrication Metals

The most commonly used metals in fabrication include steel, stainless steel, aluminum, copper, and brass. Each offers different benefits in terms of strength, flexibility, corrosion resistance, and aesthetics.

8. Best Welder for Thin Steel

When dealing with thin steel as 1mm, a TIG welder is often the best choice. It provides a high level of control, reduces the risk of burn-through, and can produce high-quality welds on thin material.

9. Welding 12 Gauge Steel

For 12 gauge steel, both MIG and stick welding are suitable options. The choice depends on the specific project, environment, and available equipment.

10. Preheating Before Welding

Preheating is done before welding to slow down the cooling rate, thus reducing the risk of cracking and internal stresses. It also minimizes the temperature difference between the welding arc and base material, aiding in the prevention of brittle and hard zones

11. Custom Welding

Custom welding is a specialized service where welding professionals create bespoke items or solve unique structural challenges according to customer specifications. It involves various techniques and materials and can range from creating custom car parts to intricate artistic installations.

12. How Do Welders Cut Metal?

Welders cut metal using several tools and techniques. These include oxy-fuel cutting, plasma cutting, and laser cutting. The method chosen depends on the type and thickness of the metal, precision required, and budget constraints.

13. The Benefits of Sheet Metal Fabrication

Sheet metal fabrication has numerous advantages. It offers high versatility as sheet metal can be cut, bent, and stretched into a wide range of shapes and sizes. It’s also efficient for mass production. Additionally, sheet metal is durable and withstands harsh environments, providing long-term value.

14. Tips for Welding Aluminized Steel

When welding aluminized steel, cleanliness is crucial. Use a wire brush or grinder to clean the area to be welded. TIG or MIG welding are good options, with silicone bronze filler rods for TIG or ER70S-6 wire for MIG. Always wear proper protective equipment, as the fumes from welding aluminized steel can be hazardous.

15. Best Inert Gas for Aluminum Welding

The best inert gas to use for aluminum welding is pure argon. It provides a stable arc and good cleaning action, while helium or a mix of argon and helium can be used for thicker aluminum sections to increase heat input and weld penetration.

16. TIG Welding Body Panels without Warping

TIG welding offers excellent control, which is vital when working with thin body panels. To avoid warping, keep the heat input low, use an adequate filler material, and tack weld along the seam before completing the weld. You might also consider back purging or using a heat sink to help manage heat distribution.