If you have ever searched “plastic shop near me” while standing in a shop with a half-finished project, you already know the truth: buying plastics is easy, buying the right industrial plastics is the part that can make or break your timeline. Industrial plastics show up everywhere in fabrication, maintenance, construction, food processing, marine work, and general industrial repair. In Kelowna and across the Okanagan, industrial plastics are used for machine guards, wear strips, conveyor guides, bushings, shims, panels, spacers, prototypes, and clean-looking clear guards where glass would be risky or impractical.

This buyer’s guide is built to help you choose industrial plastics with confidence, whether you need clear plastic sheets, a polycarbonate sheet for impact protection, plexiglass for a clean visual finish, UHMW for abrasion resistance, or acetal rod for tight tolerances. Millennium Specialty Alloys supports local projects with materials that keep work moving.

Where to Buy Industrial Plastics in Kelowna

When you are buying industrial plastics in Kelowna, the best supplier is not just a place with stock, it is a place that helps you avoid re-ordering the wrong material. The most common problems happen when someone asks for “plexiglass” but actually needs polycarbonate plastic, or they order nylon plastic for a tight-tolerance part that later shifts because moisture matters in their environment.

If you are sourcing industrial plastics, go into the conversation ready to share a few details:

- What form do you need: sheet, rod, plate, or bar?

- What is the application: guard, wear surface, spacer, bushing, liner, prototype, signage, or structural panel?

- What conditions will it face: impact, abrasion, heat, chemicals, UV, moisture, or food contact?

- What size do you need: standard sizes like clear plastic sheets 4×8, or custom dimensions?

- Do you need cut-to-size, machining, holes, countersinks, or edge finishing?

A reliable plastic supply partner will ask these questions because industrial plastic is not one-size-fits-all. If your search is “plastic supply near me” or “plastic supply,” use the call or quote request to share your environment details. It saves time and it helps you get the right industrial plastics the first time.

Sheet Plastics That Are Useful on the Job

Clear sheet materials are the most common entry point into industrial plastics. People often use the terms plexiglass, plexi sheets, acrylic plastic sheet, and polycarbonate sheet interchangeably. They are not interchangeable, and choosing wrong can lead to cracking, scratching, or premature failure.

Acrylic Plastic Sheet

Acrylic plastic is a clear, rigid sheet plastic known for excellent optical clarity and a clean, finished look. When someone says plexiglass, they usually mean acrylic plastic sheet.

Acrylic plastic sheet is often used for:

- Signage, displays, and protective partitions

- Clean-looking panels where appearance matters

- Indoor guarding where impact risk is low to moderate

- Acrylic plastic looks great and is easy to fabricate, but it can crack under heavy impact compared to polycarbonate plastic. If your panel could be struck by tools, equipment, or flying debris, acrylic may not be your best option even if it looks perfect on day one.

Polycarbonate Sheet and Polycarbonate Plastic

Polycarbonate sheet is the heavy-duty clear option in many industrial plastics applications. It is typically chosen when impact resistance is the priority. If acrylic is selected for clarity and finish, polycarbonate plastic is selected for toughness and safety.

Polycarbonate sheet is common for:

- Machine guards and safety shields

- Protective panels in high-traffic areas

- Enclosures where impact and vibration are factors

- One thing to know: polycarbonate sheet can scratch more easily than acrylic plastic sheet, depending on the grade and handling. If surface clarity must stay pristine, ask about protective film, proper cleaning methods, and whether a coated option is available.

Plexiglass and Plexi Sheets

Plexiglass is a common name people use for clear plastic sheets, most often acrylic plastic sheet. If you want to avoid confusion when ordering industrial plastics, use the material name rather than the nickname. Saying “acrylic plastic sheet” or “polycarbonate sheet” makes your intent clear and speeds up quoting and cutting.

Rod and Machining Plastics that Handle Wear

Sheets work well as panels and covers, but rods and machinable plastics are where industrial plastics become functional machine components. The goal here is usually reduced friction, improved wear life, dimensional stability, or chemical resistance.

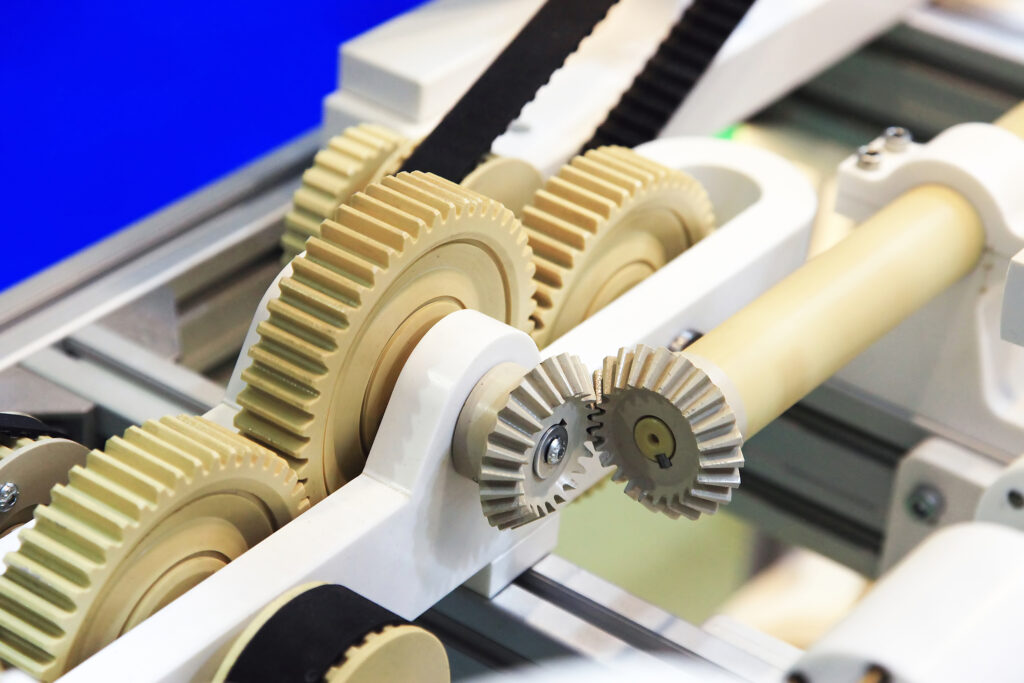

UHMW and UHMW plastic

UHMW stands for ultra high molecular weight polyethylene plastic. In everyday shop terms, UHMW plastic is a tough, low-friction, abrasion-resistant material used for sliding, guiding, and lining applications.

UHMW plastic is popular for:

- Wear strips, guides, and conveyor components

- Liners and slides where abrasion is constant

- Impact-prone environments where parts need resilience

If you are comparing industrial plastics for wear surfaces, UHMW plastic is one of the first materials to consider.

Acetal plastic and Acetal Rod

Acetal plastic is a machining favourite because it is stiff, strong, and consistent. Acetal rod is often used when a part needs to hold tight tolerances and maintain its shape.

Acetal plastic is commonly used for:

- Bushings, spacers, rollers, and precision components

- Parts with tight fit requirements

- Components where stiffness matters more than flexibility

When you need a machined part that feels “crisp” and dimensionally stable, acetal rod is a strong option within industrial plastics.

Nylon Plastic

Nylon plastic is widely used because it offers good strength and wear resistance, and it machines well. Where nylon can get tricky is moisture absorption, which can affect dimensions depending on the grade and environment.

Nylon plastic is often used for:

- Gears, wear pads, and general machined components

- Structural parts where some toughness is helpful

- Applications where cost-to-performance is a priority

If you need nylon plastic for precision parts, discuss moisture conditions and tolerances with your supplier so the industrial plastics choice matches reality.

PTFE Plastic

PTFE plastic is the low-friction, high-chemical-resistance option that shows up in tough environments. If your part deals with chemicals, heat swings, or needs an exceptionally slick surface, PTFE plastic often becomes the solution.

PTFE plastic is common for:

- Chemical exposure environments

- Low-friction liners, seals, and insulating components

- Applications needing temperature tolerance and stability

In the industrial plastics category, PTFE plastic is often selected when other materials wear too quickly or react poorly to chemicals.

Machinable Wax Plastic

Machinable wax plastic is not a final-use workhorse, but it is extremely valuable for prototyping. It machines quickly and cleanly, making it ideal for test runs, patterns, and proving a design before committing to more expensive industrial plastics.

Machinable wax plastic is often used for:

- CNC test runs and toolpath validation

- Prototypes and mock-ups

- Pattern and model work

If you are doing iterative design work, machinable wax plastic can reduce waste and speed up approvals.

Choosing the Right Industrial Plastic For Your Application

The “best” industrial plastics choice depends on what you are optimizing for. There is no universal winner. Your job is to match material behaviour to real conditions.

Use this practical selection guide:

- If impact is likely, polycarbonate sheet and UHMW plastic are common industrial plastics choices.

- If abrasion and sliding wear are constant, UHMW plastic usually performs extremely well.

- If precision machining and tight tolerances matter, acetal plastic and acetal rod are often a strong starting point.

- If moisture conditions are stable and you want strength plus wear resistance, nylon plastic can be a cost-effective choice.

- If chemicals, heat, and low friction are central concerns, PTFE plastic is often the safest option.

- If you are prototyping before final production, machinable wax plastic can save time and cost.

If you are unsure, describe the environment first, then choose from industrial plastics based on the performance traits that matter most. A supplier who understands industrial plastics will help you choose based on function, not guesswork.

Ordering Custom Industrial Plastics in Kelowna

Custom cutting is where industrial plastics become truly useful. Ordering the right size sounds simple until you need holes aligned, edges finished, or tolerances tight enough that a part fits without persuasion.

Before ordering industrial plastics cut-to-size, confirm these details:

- Final dimensions and tolerance

If you need exact fit, specify the tolerance. A rough cut and a precision cut are not the same thing. - Cut method and thickness limits

Some materials and thicknesses cut better with different methods. This affects edge quality and accuracy. - Edge finishing

Decide whether you need deburred edges, sanded edges, polished edges, or a simple as-cut edge. - Protective film handling

For acrylic plastic sheet and polycarbonate sheet, protective film matters. Confirm whether it stays on during cutting and transport. - Installation requirements

If you are mounting the material, share hole locations, countersinks, and any fastener requirements.

If you are ordering clear plastic sheets and then planning to trim on site, you may only need standard cuts. If you are ordering multiple parts for a machine guard or enclosure, tighter cutting and cleaner edges can make installation faster and safer.

Quick Checklist for Buying Industrial Plastics in Kelowna

If you want a smooth ordering experience for industrial plastics, bring this information:

- A sketch, photo, or cut list with measurements

- The material you think you need (or what you are replacing)

- The environment details: impact, abrasion, heat, chemicals, UV, moisture

- Quantity and deadline

- Any machining needs: holes, cut-outs, countersinks, edge finishing

Ready to order industrial plastics in Kelowna?

Whether you need acrylic plastic sheet for a clean, polished finish, polycarbonate sheet for impact protection, UHMW plastic for wear strips and liners, acetal rod for tight-tolerance parts, nylon plastic for everyday machining, or PTFE plastic for chemical resistance, Millennium Specialty Alloys can help you source industrial plastics that actually fit the job. Get in touch to request a quote, ask about stock in Kelowna, or send us your cut list. We’ll help you choose the right industrial plastics and get it cut to size so your project stays on schedule.