Selecting industrial plastics is a crucial step in any manufacturing project. However, with so many different types of plastics available, how can you be certain you’re making the best choice? We’ll dive into how to properly select plastics, taking you through the various considerations that are key when choosing the right plastic for manufacturing.

Understanding Industrial Plastics

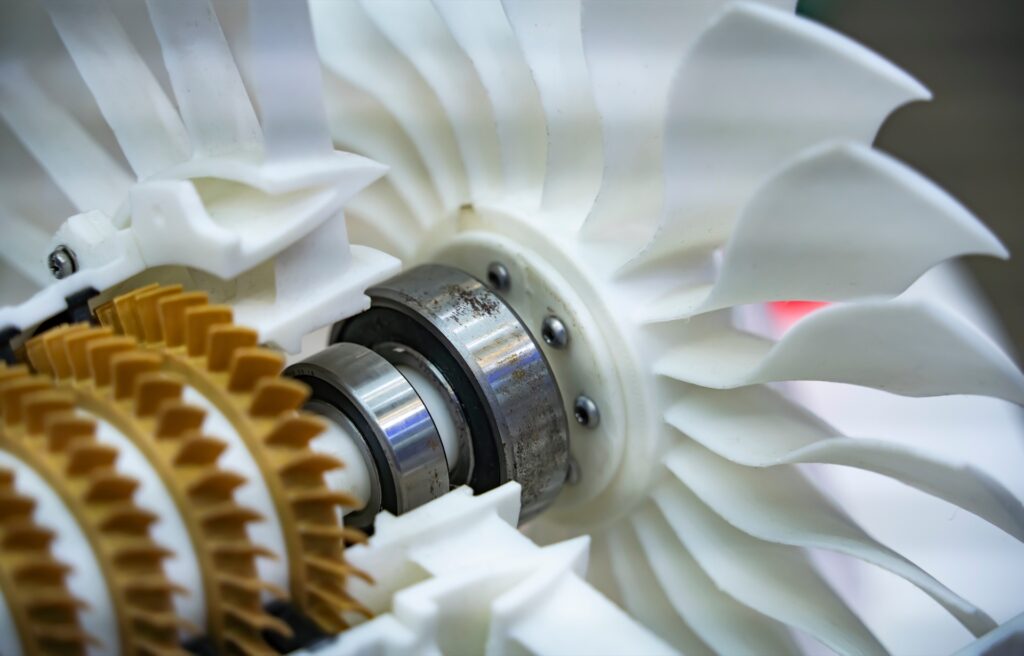

Before diving into the process of selecting the right plastic, it’s important to understand what industrial plastics are. In essence, they’re durable materials that are capable of withstanding heavy-duty usage, harsh environmental conditions, and stressors that would typically degrade other types of materials. They are designed for high performance and are commonly used in industries such as automotive, aerospace, construction, and electronics.

Key Factors to Consider When Selecting Industrial Plastics

There are several factors you should take into account when choosing a plastic for your industrial project:

- Physical properties: This includes strength, flexibility, heat resistance, and durability. Different plastics have different properties, so it’s essential to select one that meets your project’s specific needs.

- Chemical resistance: Depending on your project, you may need a plastic that is resistant to certain chemicals. Some plastics can withstand corrosive substances, while others may degrade when exposed to the same chemicals.

- Cost-effectiveness: Budget constraints often play a significant role in the decision-making process. While you want to ensure quality, you also need to keep your project economically feasible.

- Environmental Impact: The sustainability of your project may also influence your choice of plastic. Consider the lifespan of the product, the recyclability of the material, and the production process’s environmental impact.

Plastic Selection Guide

With these factors in mind, let’s delve into some of the most commonly used industrial plastics and their typical applications:

- Polyethylene (PE): PE is one of the most widely used plastics in the world due to its versatility. It’s durable, lightweight, and resistant to chemicals, making it suitable for packaging, agricultural films, and bottles.

- Ultra-high-molecular-weight Polythene (UHMW): A special type of building thermoplastics that’s non-toxic, abrasion resistant, odourless, tasteless, and is chemically resistant to many acids and bases. It’s commonly used in the food service industry in cabinetry and food containment.

- Polyvinyl Chloride (PVC): PVC is strong and durable, with excellent resistance to weathering, making it ideal for applications such as pipes, window frames, and cables.

- Polypropylene (PP): Known for its strength and high melting point, PP is often used in automotive parts, medical devices, and consumer products.

- Polystyrene (PS): PS is available in a variety of forms, including a rigid form used for disposable cutlery and a foam form used for insulation.

- Polyethylene Terephthalate (PET): PET is a clear, strong, and lightweight plastic, perfect for packaging and textiles.

Tips for Making Your Selection

Here are a few additional tips for selecting the right industrial plastic:

- Consult with an Expert: An experienced plastic manufacturer can provide advice on the best plastic for your needs, taking into consideration your project requirements, budget, and sustainability goals.

- Test Prototypes: If possible, create and test prototypes using different plastics to evaluate their performance in real-world conditions.

- Stay Informed: The world of industrial plastics is constantly evolving, with new materials and technologies being developed all the time. Keep yourself updated on industry trends to make informed choices.

Selecting the right plastic for manufacturing can be complex, but by understanding the fundamental factors that should guide your decision, you can make a choice that ensures the success of your project. Remember, the goal is to find a balance between the material’s physical and chemical properties, cost-effectiveness, and environmental impact. Whether you’re creating a new product or improving an existing one, your choice of plastic can make all the difference.