A myriad of different industrial plastics play a crucial role in various sectors and applications, including manufacturing, construction, and more. Selecting the appropriate plastic material can dramatically influence your project’s performance and longevity. We take pride in offering a comprehensive range of industrial plastic products, encompassing HDPE (High-Density Polyethylene), UHMWPE (Ultra-High Molecular Weight Polyethylene), PTFE (Polytetrafluoroethylene), and Acetal plastic. Below, we’ll examine these materials’ unique properties and how they can enhance your applications.

HDPE: The All-Rounder with Durability

HDPE, or High-Density Polyethylene, ranks among the most widely utilized plastic materials globally. Renowned for its strength, durability, and environmental resistance, HDPE can be found in applications like piping systems, plastic containers, and geomembranes. Its affordability, ease of fabrication, and recyclability render HDPE an excellent choice for industrial and consumer products alike. Key HDPE advantages include:

- Chemical Resistance: HDPE withstands many acids, bases, and organic solvents, rendering it apt for chemical processing and storage.

- Impact Resistance: HDPE’s excellent impact resistance makes it ideal for durability-demanding applications in harsh environments.

- Low Moisture Absorption: HDPE’s low moisture absorption rate curbs swelling and ensures dimensional stability in damp conditions.

UHMWPE: The Ultra-Durable Powerhouse

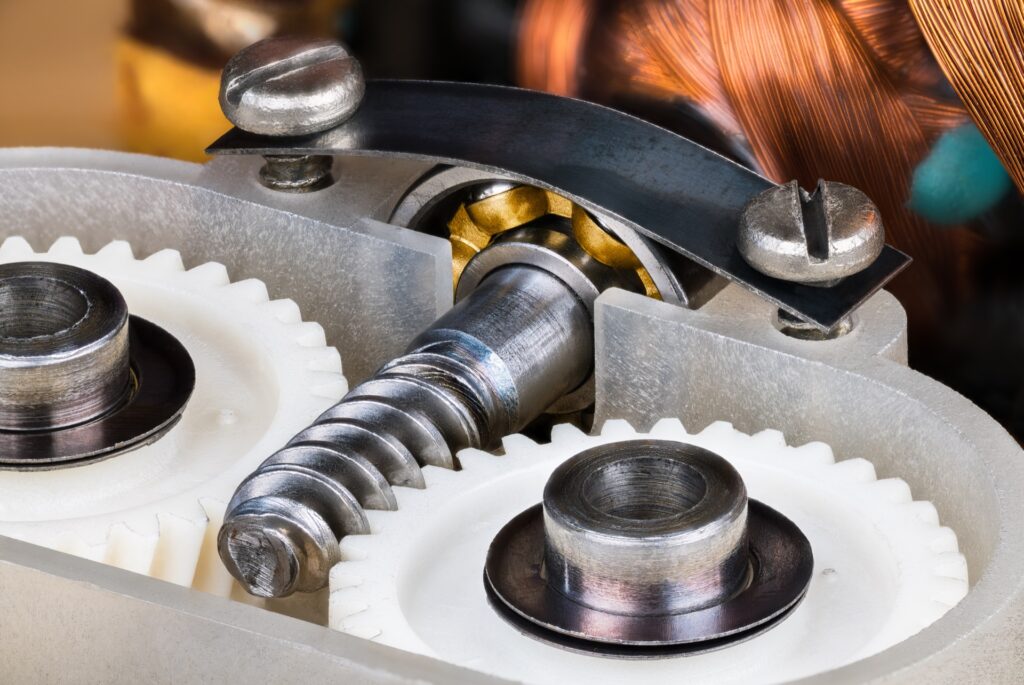

UHMWPE, or Ultra-High Molecular Weight Polyethylene, is a polyethylene variant with a higher molecular weight than HDPE, resulting in superior material properties. With exceptional wear resistance, low friction coefficient, and high impact strength, UHMWPE finds use in demanding applications like conveyor systems, bearings, and gears. Notable UHMWPE properties include:

- Abrasion Resistance: UHMWPE’s high abrasion resistance makes it suitable for sliding and high-wear applications.

- Low Friction: UHMWPE’s low friction properties minimize energy consumption in moving parts, boosting efficiency.

- Self-Lubricating: UHMWPE’s self-lubricating nature diminishes the need for external lubrication, thereby reducing maintenance demands.

PTFE: The Non-Stick Marvel

PTFE, or Polytetrafluoroethylene, is a synthetic fluoropolymer acclaimed for its non-stick properties and exceptional chemical resistance. PTFE’s unique features make it the material of choice for applications like gaskets, seals, and coatings across industries such as aerospace and food processing. Key PTFE characteristics include:

- Non-Stick Surface: PTFE’s non-stick surface lowers adhesion and enhances cleanability, making it apt for food contact applications.

- Wide Temperature Range: PTFE can endure extreme temperatures, rendering it perfect for high-temperature applications.

- Chemical Inertness: PTFE’s inertness to most chemicals guarantees long-term stability in aggressive environments.

Acetal: The High-Caliber Engineering Plastic

Acetal, or polyoxymethylene (POM), is an engineering plastic celebrated for its high strength, dimensional stability, and excellent machinability. Acetal features in precision mechanical components, gears, and bearings where dimensional accuracy and low friction are vital. Primary Acetal benefits include:

- Mechanical Strength: Acetal’s high mechanical strength and stiffness render it perfect for load-bearing applications and precision components.

- Dimensional Stability: Acetal exhibits low moisture absorption and excellent dimensional stability, making it suitable for applications necessitating tight tolerances and consistent performance.

- Excellent Machinability: Acetal’s easy machinability and fabrication allow for the creation of complex components with high precision.

As a trusted supplier of industrial plastics, Millennium Specialty Alloys is dedicated to offering our customers a broad array of high-quality materials. Whether you require HDPE for its durability and chemical resistance, UHMWPE for its toughness and low friction, PTFE for its non-stick properties and chemical inertness, or Acetal for its strength and machinability, our team is prepared to help you choose the ideal material for your application.