From soda cans made of aluminum to the aluminum foil you use in your kitchen, aluminum is pretty common in our daily lives. But just how much do you know about this common metal. Do you know where aluminum is found? And how about the process from its extraction to becoming ready for use?

While it is pretty common metal, there are some interesting facts about aluminum that we think you should know. So how about a short crash course on everything aluminum? Class is in session!

Did You Know?

Aluminum was once more valuable than gold and silver. In 1852, a kg of aluminum cost approximately $1,200 compared to a kg of gold sold at $664. President of France Napoleon III even served dinners on aluminum plates.

Where Is Aluminum Found?

Among all the metallic elements that naturally occur in the earth’s crust, Aluminum is the second most abundant metal. In its purest form, aluminum is bright and has a clear silvery appearance. However, this is not the look of aluminum most of us are used to. This is because it is extremely rare to obtain aluminum in a pure state. The moment aluminum is exposed to air it oxidizes, and this thin layer of oxidation results in the dull silvery appearance we are more acquainted with.

Even in the earth’s crust aluminum is not present in its pure form. As an element, aluminum easily bonds with other elements due to its high chemical reactivity. Therefore inside the earth’s crust, the primary source of aluminum is the bauxite ore. Bauxite occurs from the bonding of hydrated aluminum oxide and hydrated iron oxide. To obtain the aluminum metal, bauxite first undergoes chemical separation through the Bayer process to produce aluminum oxide. The aluminum oxide is then refined using the Hall-Heroult electrolytic process to obtain aluminum.

Random Fact

Aluminum weighs 1/3 as much as steel.

Properties of Aluminum

As a metal, aluminum has the following physical properties:

•Soft

•Lightweight

•Heat resistant

•Corrosion-resistant

•Fire-proof

•Conductive

•Ductile

Random Fact

Aluminum is extremely reflective. It can reflect 98% of infrared rays and 92% of visible light. This is why it is used for tubing in the manufacturing of telescopes.

Types of Aluminum

As we have already mentioned, on exposure to air aluminum oxidizes. This is the same process through which iron rusts. But unlike oxidization of iron that destroys the metal, oxidization of aluminum works to improve the quality of metal by shielding the metal from any further decay. It is with this foundation that the combining of aluminum with other metallic elements improves its quality and results in aluminum alloys.

To increase the strength of aluminum, because in its natural state it is very soft, the metal may be alloyed with copper to create aluminum bronze. To improve the ductile nature of aluminum for purposes of easy shaping, alloying with magnesium is the best option. To enhance the corrosion resistance of aluminum, the metal is alloyed with manganese through the process of anodizing to result in anodized aluminum. And while aluminum can conduct electricity, its electrical conductivity is only 63% of copper’s conductivity. Therefore to boost conductivity, aluminum is alloyed with boron.

Uses of Aluminum

The use of aluminum in terms of versatility, quantity, and value exceeds that of all other metals except for iron. Aluminum is used in almost every sector and is a very significant resource in the world economy.

Sectors that heavily rely on aluminum include:

Transportation Sector

Aluminum as a metal is lightweight. When alloyed, its strength is increased and its anti-corrosion attribute enhanced. Its extraordinary strength to weight ratio makes it perfect for the construction of the body of automobiles. Lower weight requires less force to move, thus higher fuel efficiency. The light nature of aluminum also makes it suitable for the construction of aircraft parts while its ability to resist heat damage makes it ideal for use in car and airplane engines.

Random Fact

A single Boeing-747 plane contains more than 66,000kgs of aluminum in its construction.

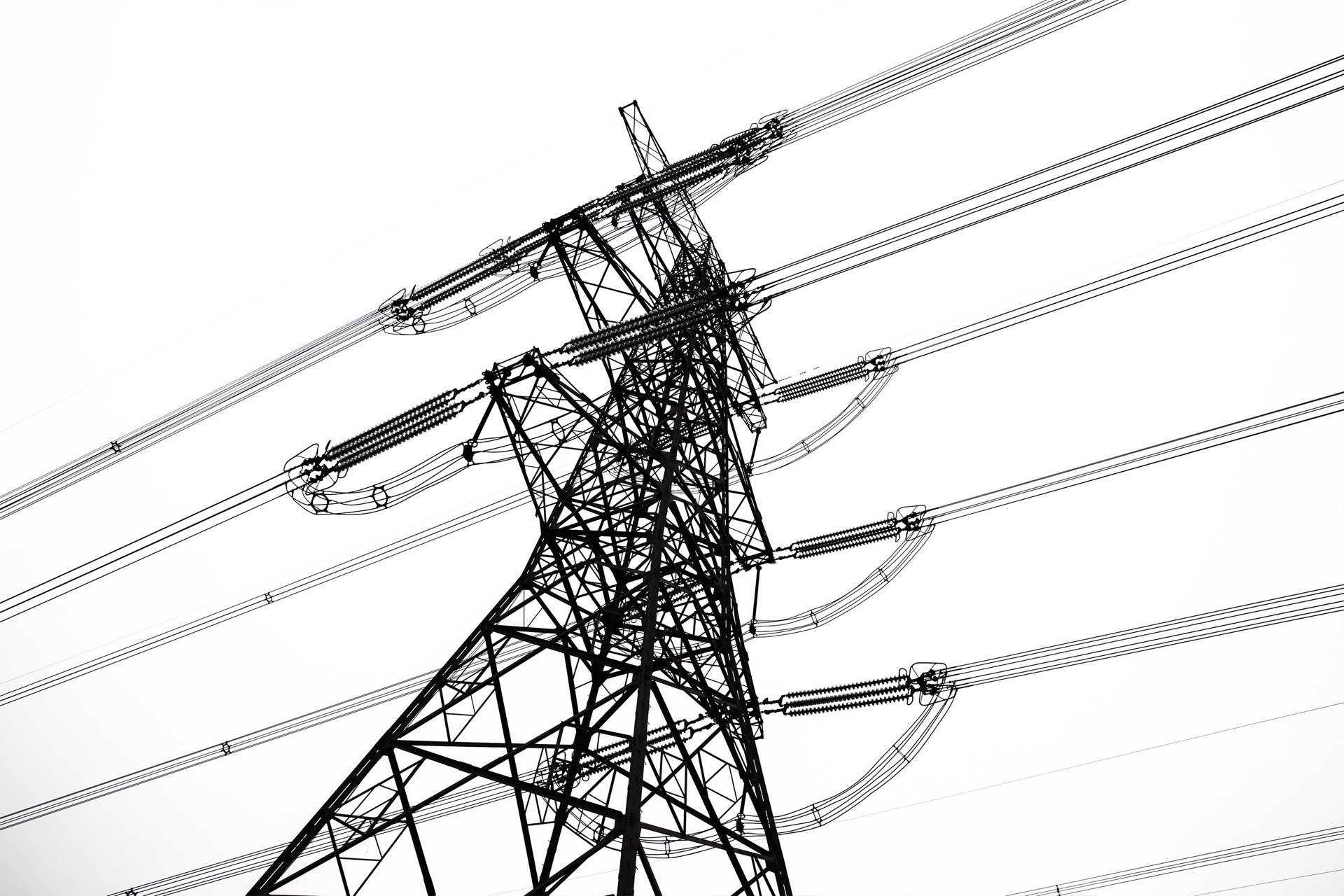

Electrical Sector

Although copper has the highest electrical conductivity, aluminum alloys can be as effective when it comes to power lines. The lightweight nature of aluminum makes it ideal for long-distance power lines to reduce the weight of the cables as well as droopiness during hot weather. The corrosion resistance of aluminum enhances the durability of power cables and lines, while its ductile nature makes it easier to shape wires for various electrical applications.

Construction Sector

Architects favour the use of aluminum in part because of the creative freedom it allows in construction. Being ductile, aluminum can be curved and welded into numerous designs, making it possible to develop buildings that would have otherwise been impossible with steel or wood. Contractors, on the other hand, prefer aluminum in construction due to its thermal efficiency that ensures buildings remain warm in the cold seasons and cool in the hot seasons.

Random Fact

The first building to have aluminum extensively incorporated in its construction was the Empire State Building of New York, constructed in 1932.

Packaging Sector

In 2012 alone, 1.9 million tons of aluminum were produced for containers and packaging in the U.S according to the U.S Environmental Protection Agency. Aluminum packaging offers an unbeatable barrier to bacteria, light, moisture, oxygen, and microorganisms. This is why the metal is widely used for packaging for both food items and pharmaceuticals. Aluminum alloy is also ductile makes it easy to form into any shape, just like the aluminum foil in your kitchen.

Consumer Goods

Manufacturers and developers of consumer goods are constantly working towards improving the function, form, and durability of their products. Aluminum is increasingly replacing steel and plastic components of consumer durables since it is lighter than steel but stronger than plastic. Aluminum’s thermal efficiency attribute makes it suitable for electronics to prevent overheating, and its ability to conduct heat makes it perfect for cooking tools.

Random Fact

Apple primarily uses aluminum parts in its production of iPhones and MacBooks.